Used in

toolboxes

desk and file cabinet

cash dispenser

Cassette tape storage

Industrial storage

Load-bearing capacity

LBS

ISO 9001

Certificate

Q235 Steel

Material

Switching Times

industrial outdoor storage

Durability

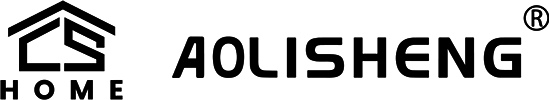

Wear-resistant and Corrosion-resistant

High-strength steel is used, and the slide rails are wear-resistant and anti-corrosion-treated to ensure their stability in long-term use. The slide rails were tested for dynamic durability through 10,000 switching operations without significant performance degradation.

In actual applications, the slides have performed well in various industrial storage cabinets, and customer feedback has also proven their durability.

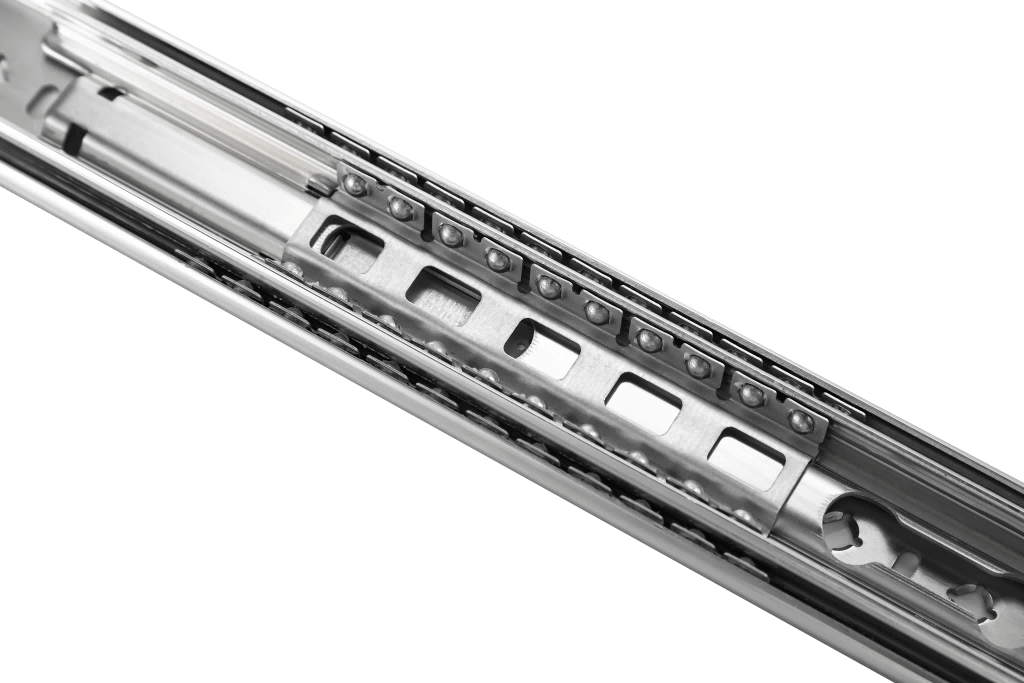

Our drawer slides are designed to provide excellent sliding smoothness. The slides are equipped with double-layer ball bearings to ensure smooth sliding during the entire use process. In our laboratory tests, the sliding resistance is maintained at around 0.5N, which can maintain smooth operation even under maximum load.

The slide rails are designed to meet a variety of size requirements, and we also provide customized services to adapt to specific size industrial storage needs.

Security

The slides can be optionally equipped with an automatic locking mechanism to ensure that the drawer does not accidentally slide or fall out when fully opened. We use high-strength steel to manufacture the slides and apply anti-corrosion treatment to improve durability and safety.

Design and Aesthetics

The slides are available in a variety of surface treatments such as electroplating, electrophoresis, polishing and brushing, showing a modern metallic luster that blends perfectly with a variety of styles. We also provide customized services, and can adjust the color, size and surface treatment of the slides according to customer needs to ensure that they match the design style of the tool box.

industrial storage

You may be interested

How do you make tool box drawers slide easier?

There are several ways to make your toolbox drawer slide more smoothly:

Clean the rails: Clean the rails of dust and debris regularly to ensure that there are no obstacles that prevent sliding. You can use a clean cloth or brush to clean.

Lubricate the rails: Apply an appropriate lubricant, such as silicone oil or a special rail lubricant, to the rails to reduce friction and make the drawer slide more smoothly. Be careful not to use too much to avoid oil stains.

Check the alignment: Make sure the drawer is aligned with the rails. If the drawer is not installed correctly, it may cause jamming. You can adjust the rails or reinstall the drawer to align them correctly.

Replace worn rails: If the rails are worn or damaged, consider replacing them with new ones to ensure that the drawer can slide smoothly.

Reduce the weight: If the tools or items in the drawer are too heavy, try to reduce the weight and spread it among other drawers to reduce the burden on the rails.

Check the installation: Confirm that the mounting screws of the rails are loose and re-tighten them if necessary to maintain the stability of the rails.

Through the above methods, you can effectively improve the sliding performance of the toolbox drawer, making it smoother and more convenient to use.

Can the material be customized?

Of course, we not only have high-strength Q235 steel as the material for making slide rails, but also stainless steel 201 material and stainless steel 304 material. If you want to use other materials, you can contact us and communicate with our professional engineers whether the material can be used.

Is the size right for my industrial storage project?

We offer up to 26 types of slides to choose from, and each slide comes in a variety of sizes. You can contact us to discuss your product size and required functions with our professionals one-on-one, and we will match the most suitable slide size for you. Of course, if your product size is special, we also provide customized slide services.