undermount drawer slides

Need a different size or load capacity? Explore our durable, smooth-gliding undermount drawer slides—Click to find your perfect match!

Undermount Soft Close Adjustable Drawer Slides - MK316

80 lbs

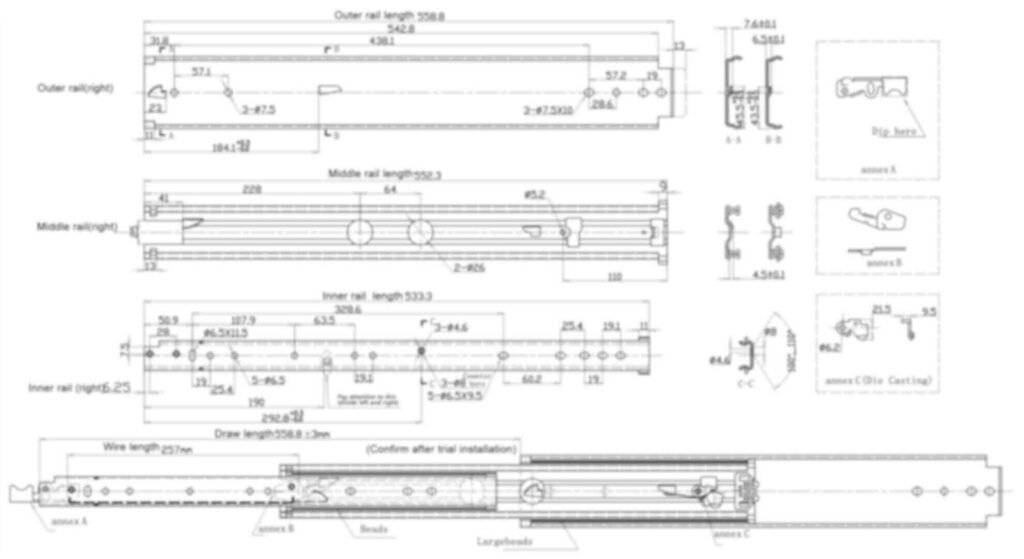

Material: Cold-rolled steel/Q235

Slide width: 42mm

Installation thickness: 5*24.5mm

Slide length: 10″ to 24″

Load bearing: 18“80 lbs (35kg)

Level of travel: Full Extension

Mounting type: Under-Mount

Customizable adjustable drawer slides size, function, hole position, color, etc.

* Allow the installation thickness of the drawer slide to no longer be limited to a single value. Adjustments enable this drawer slide to suit a wider range of scenarios and ensure smoother operation.

Application Segment

Specifically for kitchen pots, bowls, and baskets

Our Services

MOQ Offered

We provide flexible minimum order quantities, allowing you to start small and scale up as needed.

Large Inventory

Ensuring Ample Stock for Immediate Shipment, Eliminating Wait Times for Production.

Complete Specifications

We refine various specifications of drawer slides according to different usage scenarios.

AOLISHENG produces adjustable drawer slides with standard specifications and provides customized solutions to meet your project needs.

Why Choose AOLISHENG

Rich Experience

- 15 years of industry experience.

- Extensive customization experience.

Production Automation

- Over 90% automation in production.

- Production efficiency increased by more than 10 times.

Quality Assurance

- High-quality products certified with SGS and EN standards.

- Stringent inspection department.

Mass Production

- Factory area of over 40,000 square meters.

- Daily production capacity of over 100,000 sets.

Leading Quality

- Hundreds of professional production machines.

- 5 times product accuracy.

We Look Forward To Your Contact

AOLISHENG is your trusted global partner for high-quality drawer slide production, with strategic factories worldwide and professional local service teams. Partnering with AOLISHENG ensures efficient project delivery, robust supply chains, expert technical support, and a thriving customer base.

FAQ

How much weight can bottom mount drawer slides hold?

The load-bearing capacity of bottom mount drawer slides usually depends on their design and manufacturing materials. Generally speaking, common bottom mount drawer slides can withstand the following weight ranges:

Light-duty slides: Suitable for light-load drawers, generally bearing about 15 to 25 kg (33 to 55 pounds).

Medium-duty slides: Suitable for medium-load drawers, generally bearing between 25 and 45 kg (55 to 100 pounds).

Heavy-duty slides: Used for heavier-load drawers, the load-bearing capacity can reach more than 45 kg (100 pounds), or even higher.

What is the minimum clearance for undermount drawer slides?

The minimum clearance requirements for bottom mount drawer slides depend on the specific bottom mount drawer slides model and brand, but in general, here are some common minimum clearance requirements:

1. Undermount drawer Slides Clearance

Minimum Clearance: Typically, the minimum clearance required for bottom mount drawer slides is about 1/2 inch (about 12 mm) to 3/4 inch (about 19 mm). This clearance is to ensure that the drawer can be installed and slide smoothly, and avoid friction with the slide or drawer box.

2. Floor Clearance

Clearance between the drawer floor and the slide: Bottom mount drawer slides are installed at the bottom of the drawer, so you need to ensure that there is enough clearance between the drawer floor and the slide. Generally, the recommended clearance is 1/4 inch (about 6 mm) to 3/8 inch (about 10 mm) to ensure that the slide can be installed smoothly without affecting the normal operation of the drawer.

3. Installation and Adjustment

Drawer Bottom: The bottom of the drawer needs to be flat so that the slide can be installed correctly. Before installation, make sure the clearance at the bottom meets the requirements of the slide to avoid affecting the use effect.

Adjustment space: Some slide models have fine-tuning capabilities, but sufficient installation space is usually still required for adjustment and maintenance.

4. Other considerations

Furniture structure: Make sure the design and structure of the drawer box can accommodate the required clearance. If the bottom plate design or thickness does not meet the requirements, corresponding adjustments may be required.

Slide model: Different brands and models of bottom mount drawer slides may have different clearance requirements, so it is best to refer to the installation instructions of the specific product.

Summary

The minimum clearance of bottom mount drawer slides is generally between 1/2 inch (about 12 mm) and 3/4 inch (about 19 mm), while the clearance between the bottom plate and the slide is recommended to be 1/4 inch (about 6 mm) to 3/8 inch (about 10 mm).

These clearances ensure smooth installation of the slide and normal use of the drawer. Before installation, it is best to check the specific installation guide provided by the slide manufacturer for accurate clearance requirements.

Why use undermount drawer slides?

There are many advantages to using undermount drawer slides that make them very popular in many high-end and modern furniture designs. Here are some of the main reasons to use undermount drawer slides:

1. Aesthetics

Concealed Design: Undermount drawer slides are installed at the bottom of the drawer, and the slide itself is not visible from the outside. This design makes the sides of the drawer cleaner and there is no exposed slide, which makes the furniture look more modern and beautiful.

2. Smooth and Quiet Operation

Smooth Operation: Undermount drawer slides usually use ball or slider mechanisms, which can provide a very smooth opening and closing experience. The smooth operation of the slide reduces friction, making the drawer opening and closing easier.

Quiet Effect: This slide design can effectively reduce the noise when opening and closing, providing a quieter environment for users.

3. Load-bearing Capacity

High Load-bearing Capacity: Many high-quality undermount slide designs are capable of carrying large weights, suitable for drawers that need to bear weight, such as kitchen drawers, tool cabinets, etc. This makes undermount drawer slides perform well when handling heavy objects.

4. Self-adjustment function

Automatic alignment: Some bottom mount drawer slides are equipped with a self-adjustment function that can automatically correct the alignment of the drawer. This means that even if the drawer is slightly deformed during use, it can maintain smooth sliding.

5. Better storage space utilization

Internal space utilization: Since the slide is installed at the bottom, the internal space of the drawer will not be occupied by the slide, which allows the interior of the drawer to be fully utilized without being restricted by the slide support structure.

6. High-end feel and customization

High-end furniture: Bottom mount drawer slides are often used in high-end furniture and custom furniture to enhance the overall quality and grade of the furniture. Their concealed design and high performance add a high-end feel to the furniture.

Customized design: For custom furniture, bottom mount drawer slides can adapt to various design requirements and sizes, making the design more flexible.

7. Applicability

Diversified design: Bottom mount drawer slides are suitable for various types of drawers, such as shallow drawers, deep drawers, and drawers with heavy loads, etc., and have a wide range of applications.

Summary

The main purpose of using bottom mount drawer slides is to improve the aesthetics, smooth operation, and load-bearing capacity of furniture. Their concealed design, smooth operation, and self-adjusting function make the drawer experience superior, especially suitable for high-end and modern furniture. Although the price is relatively high, the design and usage advantages it brings make many users willing to invest in this type of slide.

Can drawer slides be repaired?

Repairing drawer slides is possible, but the difficulty and effectiveness of the repair depend on the degree and type of damage to the slides. Here are some common repair methods and precautions:

1. Cleaning and Lubrication

Cleaning: Sometimes the problem with the slide may be simply due to the accumulation of dust and dirt. You can use a detergent and a clean cloth to clean the slides and the inside of the drawer to remove dust and dirt.

Lubrication: Use an appropriate lubricant (such as silicone oil or grease) to apply to the slides to help the drawer slide more smoothly. When lubricating, avoid using oil-based lubricants to avoid attracting more dust.

2. Adjustment and Alignment

Adjust the position: If the drawer does not open and close smoothly, there may be a problem with the installation position of the slide. Check and adjust the position and alignment of the slide to ensure that the slide is level and properly docked with the drawer.

Screw Tightening: Check if the screws on the slide are loose and retighten them if necessary to ensure that the slide is stable.

3. Replace damaged parts

Check for damage: If a part of the slide such as the ball, slider, or bracket is damaged, the relevant part needs to be replaced. You can buy the same model of rail accessories for replacement.

Parts replacement: Some bottom-mounted rails have replaceable parts, which can be found and replaced in the rail accessories. Make sure the replacement parts are compatible with the original rail.

4. Repair or replace the rail

Minor repair: For minor damage, such as a slight bend in the rail, you can try to repair it with tools, but be careful to avoid further damage.

Overall replacement: If the rail is severely damaged or difficult to repair, it is recommended to replace the entire rail. When replacing, you need to choose a product that matches the original rail model and specifications.

5. Professional repair

Seek professional help: If the repair process is complicated or you can’t solve the problem yourself, you can seek professional furniture repair services. Professionals can provide more accurate diagnosis and repair solutions.

Precautions

Safety: Before performing any repair operations, make sure to turn off the power and operate safely to avoid damage to yourself and the furniture.

Compatibility: When replacing rail parts, be sure to confirm the compatibility of the new parts with the existing rails to ensure normal function.

Summary

Drawer slides can be repaired. Common repair methods include cleaning and lubrication, adjustment and alignment, replacement of damaged parts, and repair or replacement of the slides. The specific repair steps depend on the damage and type of the slide. For complex repairs or problems that cannot be solved by yourself, you can consider seeking professional help.

What are the drawer slides called?

There are many types of drawer slides, each with different features and uses. Here are some common drawer slide types and their Chinese names:

1. Side-Mount Drawer Slides

Side-Mount Drawer Slides: These slides are installed on the side of the drawer and are the most common type of slide. They usually have ball bearings or sliders to provide better load-bearing capacity and durability.

2. Undermount Drawer Slides

Undermount Drawer Slides: Installed at the bottom of the drawer, the slides are hidden inside the drawer, giving the drawer a cleaner appearance. They usually provide a smooth and quiet opening and closing experience, and many models have self-adjusting functions.

3. Roller Drawer Slides

Roller Drawer Slides: Use pulleys or small wheels for sliding, suitable for lightly loaded drawers. Roller slides have a simple structure and are usually used in low-cost applications.

4. Telescoping Drawer Slides

Telescoping Drawer Slides: Allows the drawer to be fully extended and is suitable for drawers that need to be fully extended. They usually have a higher load-bearing capacity and stability.

5. Full Extension Drawer Slides

Full Extension Drawer Slides: This slide design allows the drawer to be fully extended and usually includes three sections of track, suitable for applications that require full opening and closing.

6. Soft-Close Drawer Slides

Soft-Close Drawer Slides: This slide is equipped with a soft-close function, which enables the drawer to close slowly and quietly when closing, reducing banging and wear.

7. Hydraulic Drawer Slides

Hydraulic drawer slides: Use hydraulic devices to provide a smooth and slow opening and closing experience, suitable for high-end furniture and occasions that require a particularly smooth operation.

8. Heavy-Duty Drawer Slides

Heavy-Duty Drawer Slides: Designed to carry heavier items, with a higher load-bearing capacity, typically used in industrial applications or large furniture.

9. Concealed Drawer Slides

Concealed Drawer Slides: Installed inside the drawer without revealing the slide, providing a clean look, similar to undermount slides, but the specific design may differ.

Summary

These different types of drawer slides have their characteristics and are suitable for different application scenarios. When choosing the right type of slide, you need to consider factors such as drawer size, load requirements, aesthetic requirements, and budget.

Can you upgrade drawer slides?

Yes, you can upgrade your drawer slides. Upgrading your drawer slides can often improve the experience of using your drawers, increasing their load-bearing capacity, smoothness, and quietness. Here are some tips and steps on how to upgrade your drawer slides:

1. Determine the upgrade needs

Smoothness and quietness: If your current slides don’t open and close smoothly or are noisy, you can upgrade to slides that are self-adjusting and have soft-close features.

Load-bearing capacity: If your drawers become heavier, you may need to upgrade to heavy-duty slides to increase load-bearing capacity.

Aesthetics: If you want to improve the appearance of your drawers, you can choose under-mount or concealed slides for a cleaner look.

2. Choose the right slide

Slide type: Choose the right type of slide for your needs, such as under-mount, three-section, or self-adjusting.

Size matching: Make sure the length and width of the new slides match the existing drawers and furniture structure.

Load-bearing capacity: Choose a slide that meets or exceeds the drawer load requirements.

3. Prepare tools and materials

Tools: Screwdriver, level, drill (if necessary), ruler, etc. are required.

Materials: New slides, and installation accessories (such as screws, and fixings).

4. Remove the old slides

Remove the old slides: Open the drawer and use a screwdriver to remove the screws that secure the old slides. Gently remove the old slides.

Clean up: Clean the slide area to ensure that there is no residual dust or dirt.

5. Install the new slides

Measure and mark: Measure and mark the new installation position according to the installation requirements of the new slides. Make sure the installation position of the new slides is level and symmetrical.

Install the slides: Follow the installation instructions provided by the slide manufacturer to fix the new slides in the drawer and cabinet. Use a level to check whether the slides are level.

Adjust and test: After installation, adjust the slides to ensure that the drawers open and close smoothly. Test the function of the slides, including the smoothness of sliding and the quietness of closing.

6. Perform a final check

Functional check: Make sure the drawer can be fully extended and pushed in, and the slides can work properly under load.

Adjustment details: Fine-tune the alignment of the slides as needed to ensure that the gap between the drawer and the cabinet is even and the drawer opens and closes smoothly.

Summary

Upgrading drawer slides can significantly improve the performance and appearance of your drawers. By choosing the right slide type, installing it correctly, and adjusting it, you can improve the experience of using your drawers.

The upgrade process includes selecting new slides, removing the old slides, installing the new slides, and a final check and adjustment. If you are not sure how to proceed, you can also consider seeking professional help to ensure the slides are installed correctly and function properly.